- Home

- Research

Research Topics

Structural metallic materials support our daily life through different ways from automobiles, large constructions like buildings and bridges, to familiar items like home electronics, mobile phones and sports goods. As a typical metallic material, steel industry is generally thought to be well-developed. However, the almost doubled world production of steels in the past 10 years reflects its dynamic growing, which means that it is necessary to develop more advanced steels in the future.

Structural metallic materials support our daily life through different ways from automobiles, large constructions like buildings and bridges, to familiar items like home electronics, mobile phones and sports goods. As a typical metallic material, steel industry is generally thought to be well-developed. However, the almost doubled world production of steels in the past 10 years reflects its dynamic growing, which means that it is necessary to develop more advanced steels in the future.

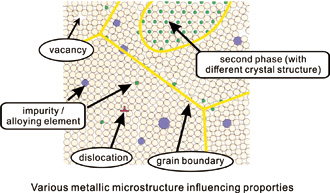

The mainly required properties of structural metallic materials when bearing heavy load is the resistance to deformation (high strength) and failure (high toughness), as well as the easiness to produce parts with complicated shape (high ductility). The factors influencing those properties are the so-called microstructural defects in metallic crystal, including grain boundary, second phase, etc. With the help of advanced analytical techniques, our laboratory aims to develop structural metallic materials with more desirable properties, based on the experimental and theoretical clarification of the microstructural evolutions as well as the microstructural control through optimized process and alloy addition.

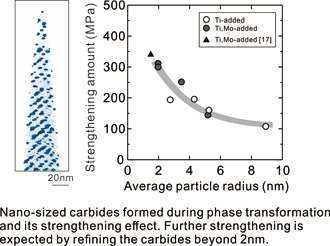

Strengthening of steels for automobiles by nano-sized carbides

In order to improve collision safety and reduce fuel consumption of transportation equipment like automobile, strengthening of steels which account for 70% of its body is strongly desirable.

In order to improve collision safety and reduce fuel consumption of transportation equipment like automobile, strengthening of steels which account for 70% of its body is strongly desirable.

In this aspect, our laboratory is studying the microstructure and mechanical properties of the steels with nano-sized carbides to realize the strengthening of steels for automobiles. Through the observation and quantitative analysis of nano-sized carbides by using electron microscope 3-dimensional atom probe, it was found that strengthening amount becomes continuously larger with finer dispersion of the carbides. The precipitation strengthening mechanism is becoming increasingly clearer.

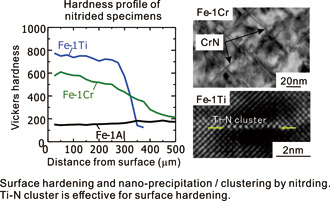

Surface hardening of steels by nano-cluster

In the application of machine parts like gears and crankshafts, surface hardening in addition to the strengthening of the bulk is effective since load and abrasion are concentrated on the surface. To satisfy the demand of high strength and high accuracy, instead of the conventional carburization process, surface hardening by nitriding process with smaller strain without variation in shape attracts more and more attention.

In the application of machine parts like gears and crankshafts, surface hardening in addition to the strengthening of the bulk is effective since load and abrasion are concentrated on the surface. To satisfy the demand of high strength and high accuracy, instead of the conventional carburization process, surface hardening by nitriding process with smaller strain without variation in shape attracts more and more attention.

Our laboratory is investigating the alloying effects on the microstructure and surface hardness by nitriding process. Through microstructural observation by using electron microscope, the reason for surface hardening was found to be the formation of mono to several atomic layers of nano-cluster. The relationship between its formation condition and hardness increment is being clarified.

Establishment of method for microstructural control by phase transformation in steels

In the strengthening of steels, we try to establish the method to refine the microstructure, e.g. by using the element partition to stabilize austenite during phase transformation, by alloy addition or thermomechanical process to control the transformation kinetics, etc.

In the strengthening of steels, we try to establish the method to refine the microstructure, e.g. by using the element partition to stabilize austenite during phase transformation, by alloy addition or thermomechanical process to control the transformation kinetics, etc.

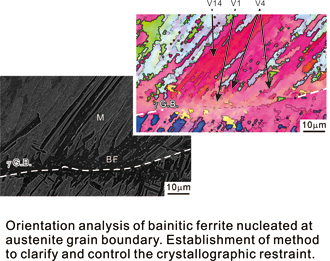

Through quantification by advanced analytical techniques, our laboratory is clarifying the crystallographic restraint during nucleation, nano-scale element partition, segregation of alloy elements to defects, etc. Based on thermodynamic, crystallographic and diffusional theories, we are carrying out fundamental research to control these phenomena.

Development of novel method for microstructural characterization

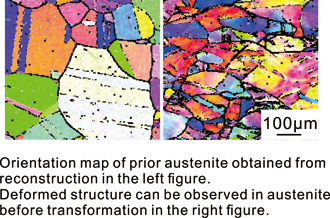

The microstructure of steels can be controlled by utilizing the phase transformation from austenite during cooling. However, the problem is the absence of austenite remained at room temperature, so that it is hard to know the transformation behaviors by normal experimental methods. Our laboratory focuses on the specific orientation relationship between austenite and product phase formed by diffusionless transformation. Based on the orientations of product phase through electron backscatter diffraction measurements, we developed a method to reconstruct the orientation of austenite. By using this method, it is also possible to reconstruct the deformed structures of prior austenite.

The microstructure of steels can be controlled by utilizing the phase transformation from austenite during cooling. However, the problem is the absence of austenite remained at room temperature, so that it is hard to know the transformation behaviors by normal experimental methods. Our laboratory focuses on the specific orientation relationship between austenite and product phase formed by diffusionless transformation. Based on the orientations of product phase through electron backscatter diffraction measurements, we developed a method to reconstruct the orientation of austenite. By using this method, it is also possible to reconstruct the deformed structures of prior austenite.