- Home

- Equipment

For thermomechanical processing

-

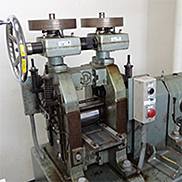

Rolling machine

DBR100A produced by Daito

Small laboratory-mill with rolls for hot and cold rolling (roll diameter:100mm, max load:20tons).

-

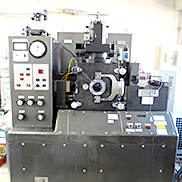

Plasma-nitriding furnace

JIN-1S produced by NDK

Furnace for plasma nitriding treatment equipped with N2, Ar, H2 gas flow system. Temperature is controlled by Pyrometer.

-

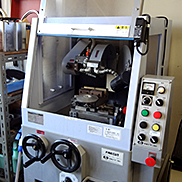

Gaseous nitriding, carburizing and quench furnace

produced by Toei Scientific Industrial Co.,Ltd.

Vertical tube furnace for gaseous nitriding, carburizing and quench processes in NH3 and H2, Ar gas mixtures. Atmosphere is monitored by H2 sensor. Specimens can be quenched directly into water/oil without being exposed to air.

-

Gaseous nitriding, carburizing and quench furnace(No.2)

produced by Toei Scientific Industrial Co.,Ltd.

※In preparation

-

Carburizing furnace(No.4)

Produced by Toei Scientific Industrial Co.,Ltd.

CN-30-2KW-3Vertical furnace to carburize or decarburize the specimen under the mixture of CH4,CO, CO2, H2 atmosphere. After the treatment, specimens can be quenched directly into water/oil without being exposed to air

-

High-speed hot deformation simulator

Thermecmaster Z produced by Fuji Electronic Industrial Co.,Ltd.

Programmed induction heating and cooling (gas or water) system with uniaxial compression dies. Strain and strain rate can be also programmed.(Max. load: 1 ton)

-

Quenching dilatometer

DIL805L

BahrThis equipment allows for the measurement of transformation temperature and thermal expansion coefficients by monitoring sample length during heating / cooling via high-frequency induction heating. It also supports rapid cooling using Ar or He gas quenching, as well as sub-zero treatment with liquid nitrogen.

-

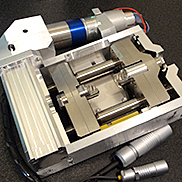

Wire electrical discharge machine

HS-70A produced by Brother Industries, Ltd.

Specimen is cut by electrical discharge between specimen and thin wire so that various shapes of specimens can be prepared.

-

Horizontal tube furnace.

Tube furnace produced by Koyo Thermo Systems Co.,Ltd.

Temperatures are controlled at three points in the furnace independently in order to archive uniform temperature distribution.

-

Cutting machine

HS-45A C produced by HEIWA TECHNICA CO.,Ltd.

Automatic cutting machine for relatively large specimen.

Property characterization

-

Room & high temperature tensile testing machine

Autograph 5000B refreshed produced by Shimadzu Corporation.

Tensile machine with infrared furnace. (Max. load: 5 tons)

-

Tensile machine equipped with a non-contacting extensometer.

Autograph AGX-100KNV

by Shimadzu Corporation.※In preparation

-

High temperature tensile deformation and quenching system

Produced by Toei Scientific Industrial Co.,Ltd.

Horizontal tensile machine equipped with an infrared heating furnace and water quenching system. Specimens can be deformed at high temperatures and subsequently quenched by water.

-

Automatic Vickers hardness Tester

AMT-X7AFS produced by MATSUZAWA CO.,Ltd.

Hardness tester equipped with automatic stage, auto focusing and scanning systems.

-

Differential Scanning Calorimetor

DSC404 F3 Pegasus produced by Netzsch

DSC equipped with vacuum pump and gas controlling system. The highest temperature for measurement is 1550oC.

-

Nano-indentation

Ti-950 produced by Hysitron

Local mechanical properties can be analyzed from load-displacement curve, which is taken at very small load.

-

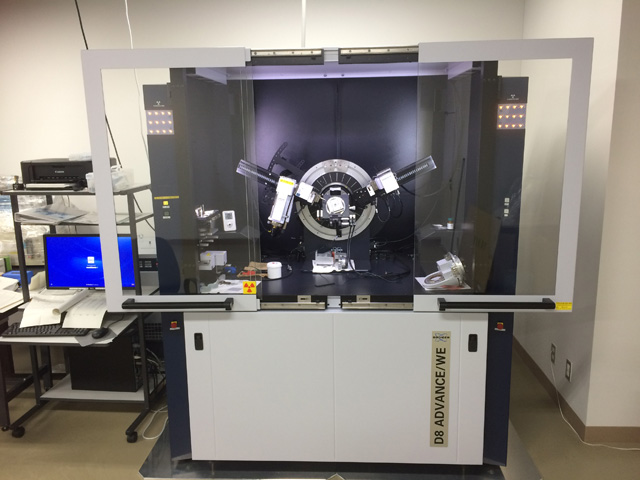

X-ray differactometer

ADVANCE D8 produced by BRUKER

※In preparation

-

Wear property evaluation (ball on disk)

FPR2200 produced byRhesca

※In preparation

-

Surface roughness measurement

SV-3200 produced byMItsutoyo

※In preparation

Microstructure analysis

-

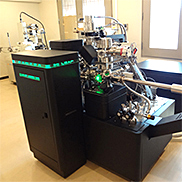

Three-dimensional atom probe

LEAP 4000HR produced by Ametek

Voltage-pulse atom probe equipped with local electrode and energy compensated reflector. Three-dimensional position of each atoms and its atomic species can be analyzed simultaneously so that nano precipitation or element partitioning can be investigated in nano-scale.

-

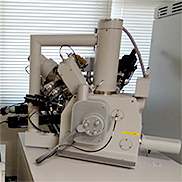

Dual Beam SEM/FIB

Quanta3D produced by FEI Co. Ltd.

Equipped with EBSD, carbon and Pt deposition systems. This microscope is used for specimen preparation for 3DAP and TEM observation as well as serial-sectioning for reconstructing three-dimentional crystal orientation.

-

FE-SEM/EBSD

JSM-7001F produced by JEOL Ltd.

Conventional FE-SEM equipped with TSL OIM system.

-

TEM

JSM-2100plus produced by JEOL Ltd.

Conventional TEM equipped with CCD camera, two axis stage, heating stage, cooling and tensile-stage.

-

FE-EPMA

JXA-iHP200F produced by JEOL Ltd.

An EPMA system capable of quantitative elemental distribution analysis with high spatial resolution. It is equipped with a soft X-ray spectrometer for light element analysis, a plasma cleaner, and a liquid nitrogen trap.

-

Laser microscope with heating stage for in-situ observation

Laser microscope (VL2000DX) produced by Lasertec

Heating stage (MS-TPS) produced by YONEKURA MFG Co.,Ltd Microstructure change on the surface of the specimen during heating and cooling can be observed in-situ by laser microscope. (temperature R.T.-1500oC)

-

Electro-polishing machine (Tenupole 5)

Tenupole 5 produced by Struers

Thin foil for TEM observation can be prepared easily by twin-jet polishing by monitoring voltage and current.

-

Ion milling

PIPS691 produced by Gatan

Disk specimen is thinned by Ar-ion milling.

-

In-situ tensile stage for SEM

TS-2000 produced by TSL solutions

Microstructural change during tensile deformation as well as displacement – load curve can be analyzed in-situ by SEM or SEM/EBSD.

-

Automatic mounting system

SimpliMet XPS1 produced by Buehler

Temperature and pressure can be programmed so as to mount the specimen in resin quickly.

Others

Vacuum furnace, box furnace, salt bath, vacuum encapsulation system, polishing / microscopy equipments,ThermoCalc, DICTRA, Analysis, Avizo etc.